Sprue pickers

- Home

- Sprue pickers

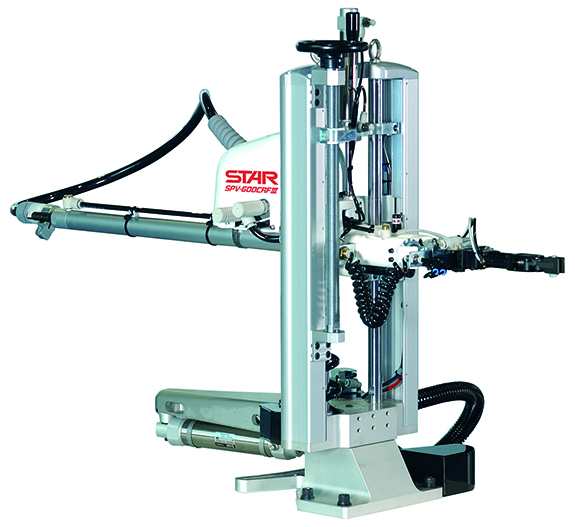

Sprue pickers – SP-FVI series

Sprue pickers are fast during extraction operations (lower than 0.8 sec on average) and only require a low-cost investment; they represent the first approach to the automation of an IMM.

They can separate the moulded part from its sprue and they can also be equipped with a vacuum generator, which allows to take the moulded part properly.

Reliable and user-friendly

The possibility to regulate the arm’s rotation angle allows to easily cross over the IMM safety protections and extract sprues. The release side can be easily modified according to the customer’s specific needs.

Moreover, the integrated sprue presence sensor on the sprue gripper guarantees the correct extraction.

CONTROLLER: STEC S2

Language switching between three language can be used for display, bascially used language are Japanese, English, and chinese (Simplified)

Memory for up to 30 different mold is possible.

Use USB to download program, backup/upload the data of replacing mould.

Safe reboot and reduction of recovery time with emergent power source.

Very user-friendly thanks to its operative modes’ programmes.

Don’t forget the end-of-arm tooling!

The most innovative Japanese technology is at the base of our Eins range, a line of products dedicated to the components for end-of-arm toolings. All Eins products are totally compatible with other brands and can also be used on robots made by other manufacturers, to get the best flexibility of use.

Contact With Us

Contact with Us

Make an Appointment

.jpeg)